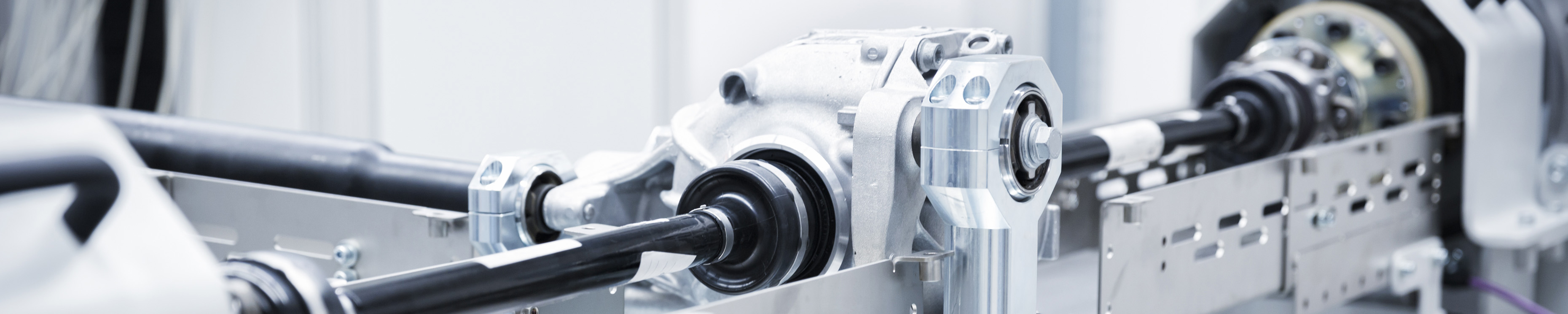

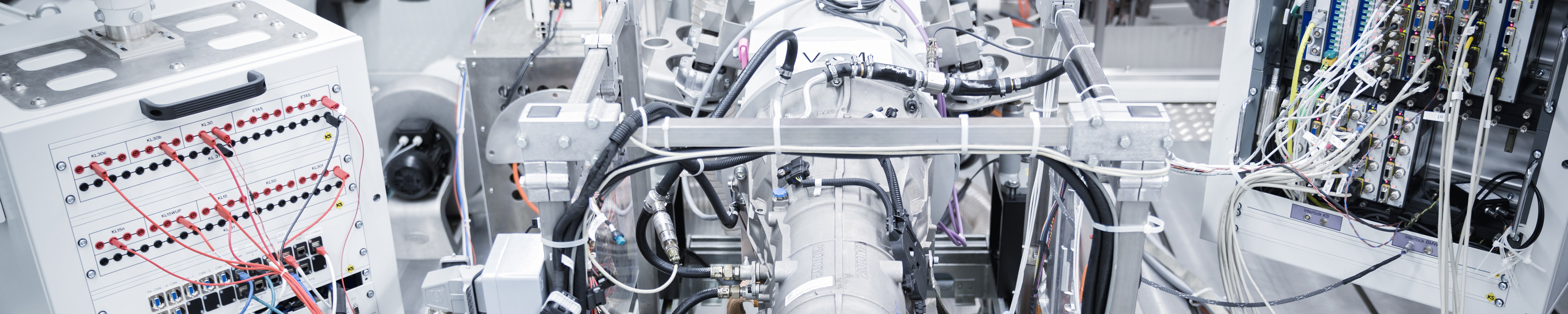

System test beds

Everything integrated

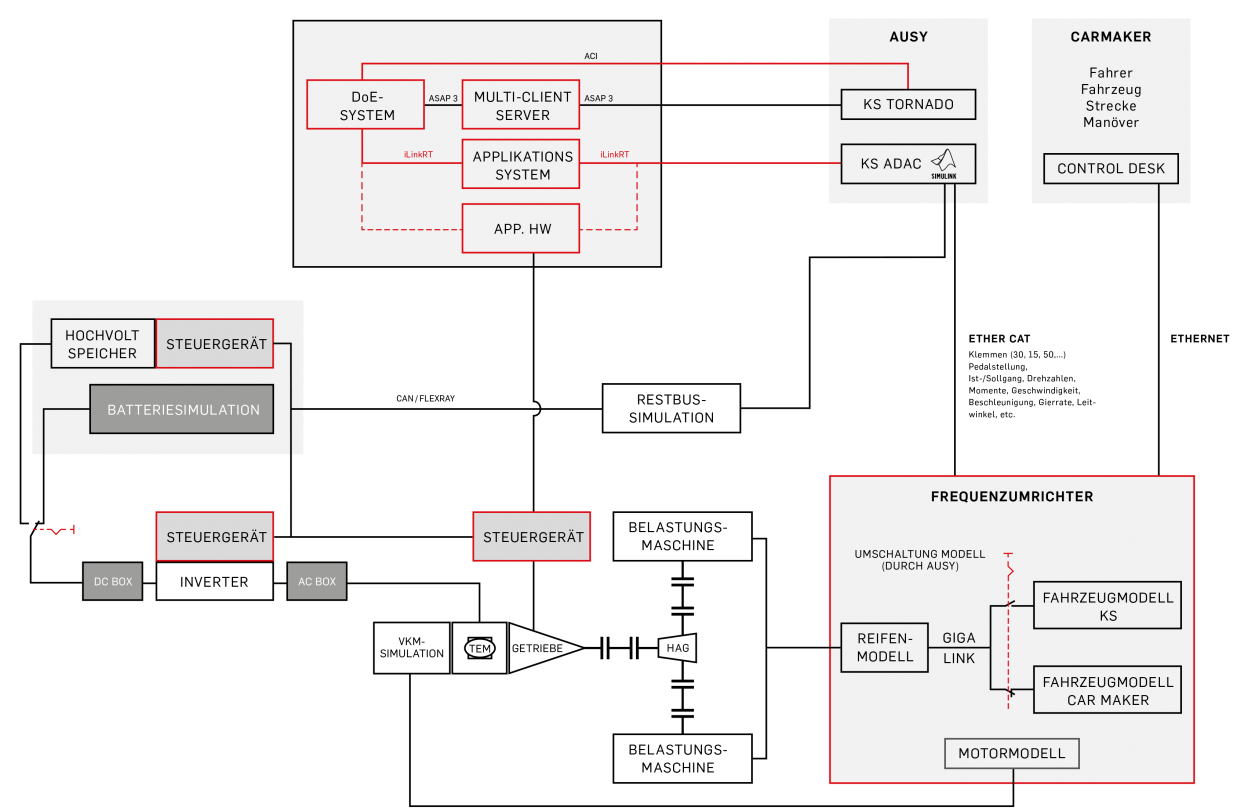

Testing of complete systems, integration of control units, simulation of components, accurate and synchronous data acquisition and processing up to 10 kHz.

KS system test beds combine our best products and extensive expertise from all the disciplines in the company. They enable the greatest possible flexibility in the tests to be performed and configurations to be used, both in relation to the setup and the possible scenarios for the unit under test. All the subassemblies, control units and other components in the unit can be actually integrated in the test bed or simulated with appropriate hardware and software, depending on the setup.